HE-PP HT

ApplicationCertificates

Automotive industry and equipment subcontractors

Application areas

- Installed in Eisenmann, Dürr, Geico…

- Used in filtration stages requiring resistance to temperature

- Used in ovens, drying zones, or near heating areas (such as make-up)

- Silicone-free (approved by a large number of automotive manufacturers)

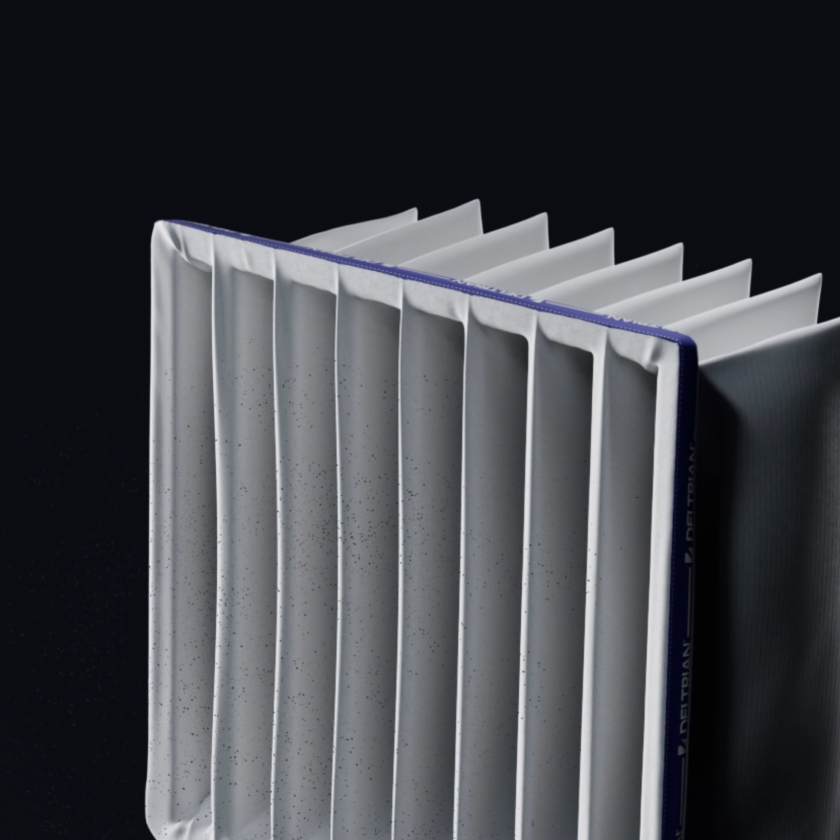

- Large filtration area

- High efficiency

- Careful and robust execution

General Characteristics

ISO16890: 2016 filtration class

Media: deep pleats made of fiberglass

Frame: galvanized

Seal: dynamic

Separators: aluminum

Grilles: protection and maintenance at air inlet and outlet

Final pressure drop according to EN 13053: initial pressure drop + 100 Pa or initial pressure drop x3 (whichever is smaller).

* Energy consumption, kWh/year: calculated according to Eurovent Guideline 4/21-2018 | ** Energy class: according to Eurovent RS4/C/001-2019 | *** Energy class: according to Eurovent RS4/C/001-2015

Application areas

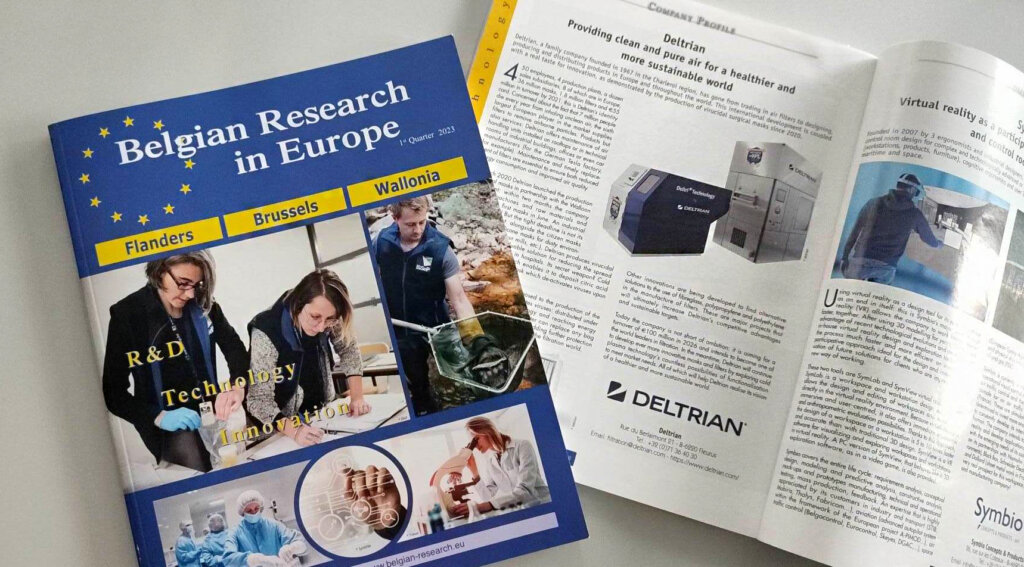

An air filtration system adapted to each sector

TFM® Service

Choose TFM® and benefit from a comprehensive maintenance contract for air filtration.

Need clean air in your workplace? With the TFM® contract, you will benefit from high-performance air filters tailored to your needs, scalable services, and dedicated teams to advise you on the installation of new equipment.

Do you have any questions? Our team is here to help.

Our experts are available to answer all your questions.