Air filtration systems in the pharmaceutical industry.

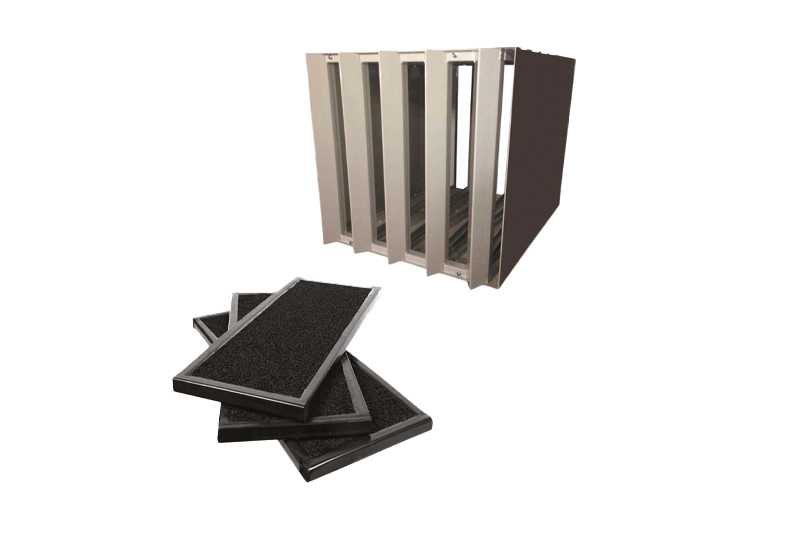

Air filters meeting the requirements of the pharmaceutical industry

Deltrian is committed to offering you air filters that protect your pharmaceutical products and employees. We have designed powerful air filtration systems that meet your production requirements and regulatory standards.

A highly regulated sector requires adapted expertise

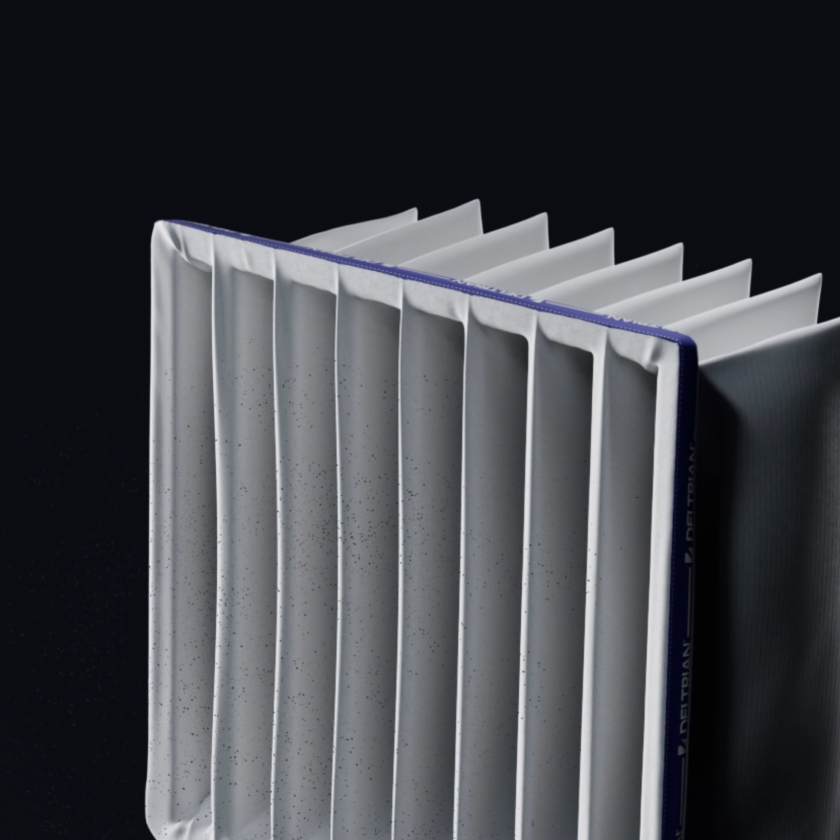

Elimination of particles

Remove suspended particles to protect your equipment and air distribution systems.

Zero margin of error for cleanliness

The pharmaceutical production environment must be extremely clean and highly regulated.

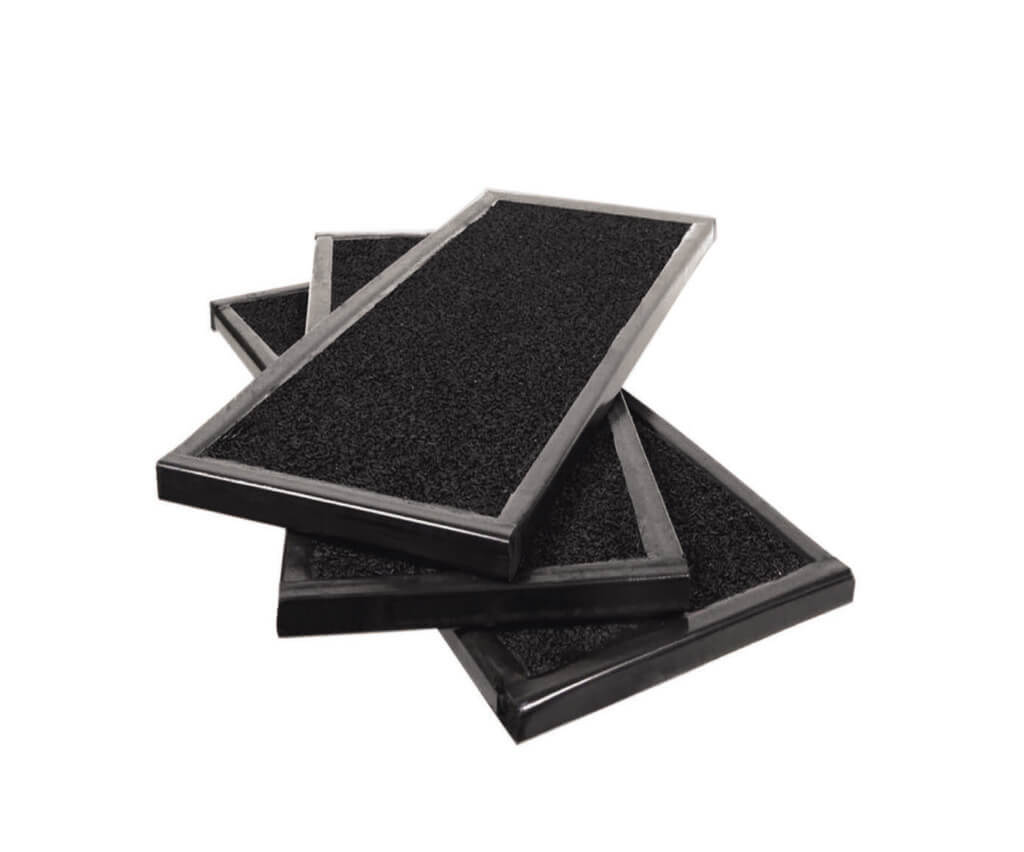

Resistance to cleaning products

Our filters meet the sanitary requirements of the pharmaceutical industry and cleanrooms.

Reducing contamination risks

Deltrian products reduce the risks of contamination, protecting consumers, operators, and the environment.

Improved safety

Our filtration systems are designed to meet the safety requirements of pharmaceutical manufacturing processes.

Reducing production costs

Our pharmaceutical air filters reduce energy consumption and equipment downtime.

Choose TFM® Service and benefit from a complete maintenance contract for air filtration.

Total Filtration Management®

Need clean air in your professional environment? With the TFM® contract, you will have access to performant air filters tailored to your needs, evolving services, and dedicated teams to assist you in the installation of new equipment.

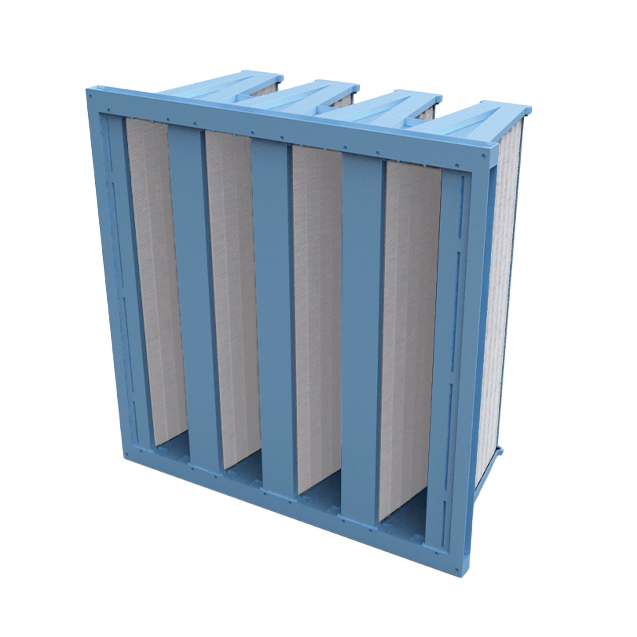

Choosing a suitable air filtration system

Rules, standards, and production imperatives.

The pharmaceutical environment is highly regulated: ISO 846 and VDI 6022 are just two examples. Air is a vector of contamination, and air filtration systems in the pharmaceutical industry must meet these requirements. The safety of installations, operators working on the production line, in laboratories, cleanrooms, and end consumers whose health problems need appropriate solutions, are at stake.

Do you suspect contamination? We have a solution!

Do you suspect contamination? We have a solution!

Faced with numerous harmful chemicals such as bisphenol or phthalates, microbial proliferation, or cleaning chemicals that can contaminate medicines, it is essential that the air is pure. The release of chemicals into the atmosphere must also be avoided! That’s why Deltrian air filters are designed to meet very high levels of requirements specific to the codified pharmaceutical industry. This is also essential for the productivity of drug production chains, which require ever more agility. A reliable air filtration infrastructure minimizes equipment downtime and optimizes processes.

Advantages of Deltrian air filtration systems

The pharmaceutical industry's requirements oblige us to adapt to offer you customized air filtration systems.

Regarding high-risk areas of the pharmaceutical industry, terminal filtration must be handled by at least H13 category HEPA filters. And this applies to all levels: crushing, mixing, formulation, compression, coating, conveying, loading zones, etc. Our filtration systems allow you to protect critical zones, ensure the smooth running of processes in cleanrooms, protect your employees, guarantee the sanitary quality of storage warehouses, etc.

- Ecological and highly efficient filters

- Resistance to chemicals used in the pharmaceutical industry

- Guaranteed safety for pharmaceutical industry procedures

Do you have any questions? Our team is here to help.

Our experts are available to answer all your questions.