A production unit of 30 million masks in Wallonia.

With financial assistance from the Walloon Region, the Charleroi-based company Deltrian will launch the production of surgical masks at the end of May.

Published on 31.03.2020

Table des matières

Fin mai

Decontaminate used masks

Jean Kalyvas

Chief Information and Marketing Officer

Too dependent on foreign actors for the supply of masks for its healthcare workers, the Walloon Region has decided to establish a mask production unit in Wallonia. The project, put together at lightning speed by SRIW and Sogepa since the beginning of the crisis, was approved by the PS-MR-Ecolo government. Production could start at the end of May, or even a little earlier.

Fin mai

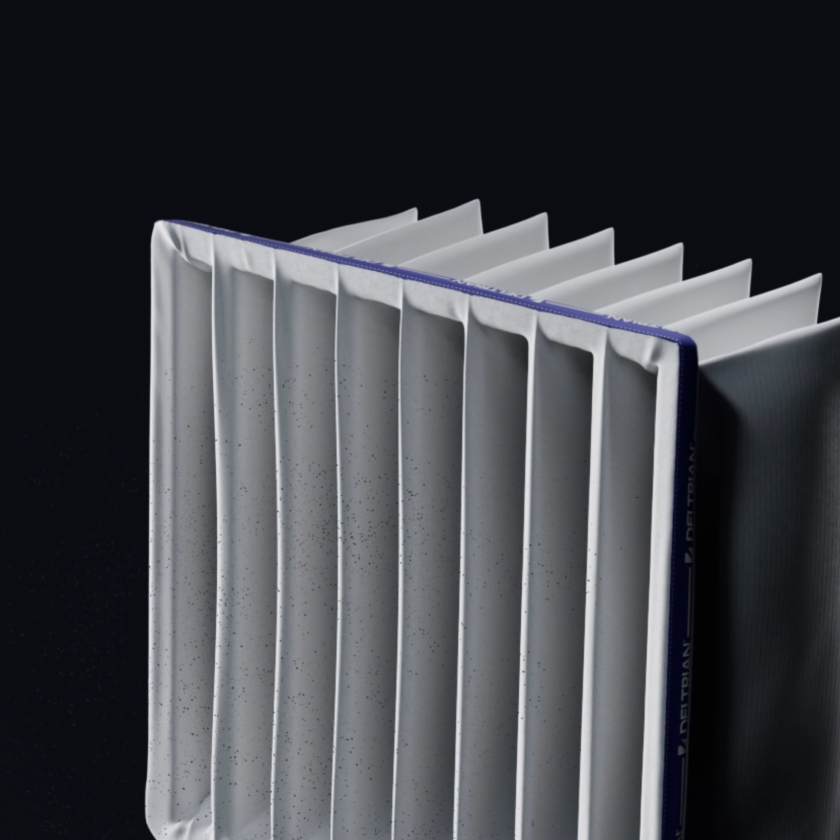

Concretely, the production will be split across two lines and will be operated by Deltrian protective equipment, a new subsidiary of the company Deltrian International, in which the Region will own 49%. This company based in the Charleroi region is active in air filtration. With the help of the Walloon Region and its financial tools, Deltrian will acquire the machines in Germany. The financial plan of the joint venture provides for an investment of 1.2 million euros. In addition to 49% of the company’s capital, which amounts to 250,000 euros, financial tools have granted a loan of 450,000 euros.

On the ground, the unit will produce 30 million surgical masks per year. The viability of the project is guaranteed by completely automated tools.

"We are in cost prices comparable to what is found on the market outside of a crisis period."

— Olivier Bouchat, vice-president of the SRIW management committee

Decontaminate used masks

In parallel with industrial mask production, the Walloon government still hopes to quickly finalize the launch of a decontamination sector for used surgical and respiratory protection masks (FFP2/3). Five types of methods (gamma irradiation, UV irradiation, ethylene oxide, dry heat, and plasma) have been scientifically tested by the CHU of Liège, 3 companies (Sterigenics, AMB Ecosteryl, Lasea), and 2 research centers (Materia Nova, CentexBel).

AMB Ecosteryl’s project is based, for example, on decontamination by dry heat. Exposed to 70 ° for 30 minutes, the coronavirus does not resist. The process should allow healthcare workers to sterilize their own equipment before reusing it. The idea is to be able to multiply the life of the masks by two or three thanks to this decontamination process.

The protocol developed by all these actors will be submitted to the Federal Agency for Medicines and Health Products (AFMPS) as of this Wednesday.

"If this avenue is validated by the Agency in the coming days, the decontamination process can be operational in three weeks"

— The Walloon government

Jean Kalyvas

Chief Information and Marketing Officer

Do you have questions? Our team is here to help you.

Our experts are at your disposal to answer all your questions.