Wallonia wants to produce its own masks.

Industrial actors are working to install a production line for masks in Wallonia. Ideas are also being studied to launch a decontamination sector for equipment.

Published on 24.03.2020

Table des matières

Univercells and Deltrian

A decontamination sector

Jean Kalyvas

Chief Information and Marketing Officer

The call dates back to a week ago, at the beginning of the coronavirus crisis in Belgium. Faced with the shortage of masks in the country and dependence on China for equipment supplies, some Walloon politicians, such as Health Minister Christie Morreal (PS), quickly suggested the idea of setting up an industrial mask production line in the southern part of the country. Her colleague in charge of the economy, liberal Willy Borsus, shares this vision and goes even further by estimating that a series of industrial activities will have to be re-territorialized in Wallonia after the crisis.

That’s the context. Faced with the urgency, the call made by the Walloon government was quickly relayed to entrepreneurs by Biowin, the biotech competitiveness cluster.

"We were approached by the government to analyze the possibilities of redeploying a mask production line in Wallonia."

— Sylvie Ponchaut, Director of Biowin

Univercells and Deltrian

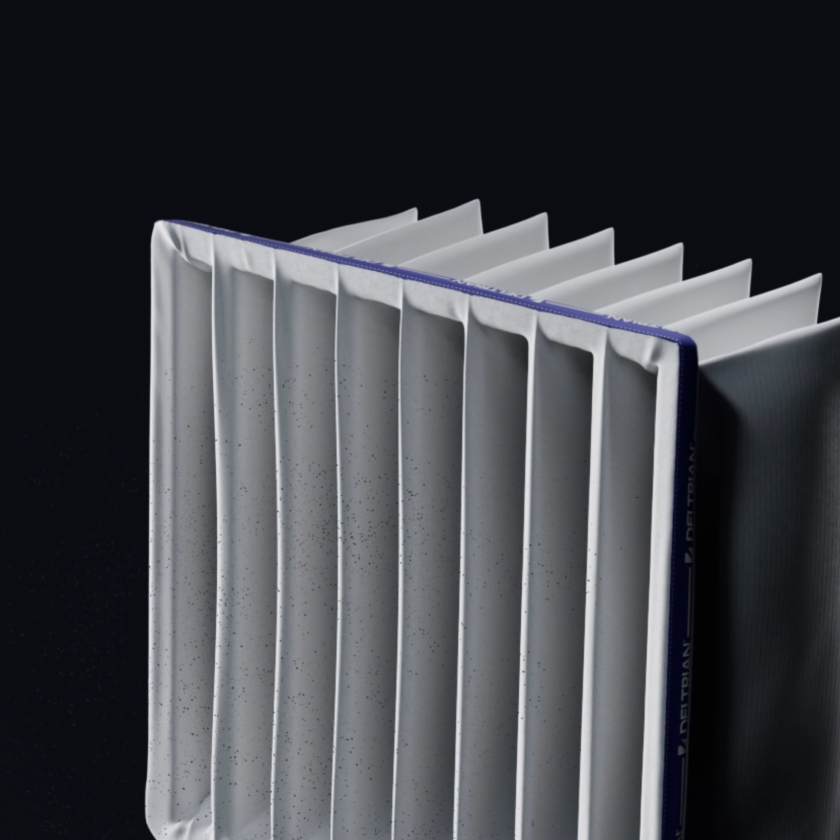

Since this call, telephone meetings have been taking place. With the support of Walloon financial tools – SRIW and Sogepa – a project is being studied with industrial players, including the biotech Univercells, specialized in vaccine production, and the group Deltrian, a specialist in filtration systems.

"We have identified machines in China that we can quickly bring back."

— Hugues Bultot, CEO of Univercells

Aware of the role that entrepreneurs have to play in overcoming this crisis, Hugues Bultot, the director of Univercells, has set up a project in just a few days. “We have identified machines in China that we can quickly bring back. We can also develop a white zone quickly. We also know the specifics of textiles. We manipulate it to make bioreactors. We are clearly available to public authorities to help even though our specialty is in vaccines. We can find solutions together. We are ready to help set up such a project. The world will work tomorrow on a different paradigm with relocations. So we must work today on a long-term vision. I believe in this new paradigm. That’s why I’m involved in this project.”

"Maybe we'll have to accept the price of autonomy. We are currently talking about a shortage of masks in hospitals, in vaccine production companies, etc."

— Sylvie Ponchaut, Director of Biowin

Behind this mobilization, political decision-makers now intend to analyze the economic feasibility of such a project. “We must, in particular, question the sustainability of this line with an acceptable cost price outside the crisis period,” says SRIW. But, as Sylvie Ponchaut points out, “maybe we’ll have to accept the price of autonomy. We are currently talking about a shortage of masks in hospitals, in vaccine production companies, etc. If we group all this demand at the level of the same production line, there is probably a way to arrive at a viable project. Perhaps not at the same price as we paid the Chinese, but we will at least have a production capacity and autonomy.

A decontamination sector

In addition to the industrial track, Walloon officials have launched a parallel reflection on a mask decontamination sector. The Walloon government has brought together three industrial players (Lasea, Sterigenics and Ecosteryl) around three research centers (Materia Nova, Giga and Centexbel) and the University Hospital of Liège.

"Technical trials are underway to establish a protocol to be submitted to the Federal Agency for Medicines and Health Products (AFMPS)."

— Minister Borsus' office.

Source: L’Echo: La Wallonie veut produire ses masques

Author: François-Xavier Lefèvre

Jean Kalyvas

Chief Information and Marketing Officer

Do you have questions? Our team is here to help you.

Our experts are at your disposal to answer all your questions.